ABOUT US

Dental Implant Manufacturer

Retech has established a world-class production line, featuring Swiss-made TORNOS and Japanese CITIZEN and STAR sliding headstock lathes. Our equipment fully aligns with the standards of top-tier international implant manufacturers, ensuring exceptional precision and robust production capabilities.

Our turning center is equipped with over 40 professional imported cutting machines, more than 30 personalized abutment cutting and polishing machines, and over 10 sets of inspection and calibration devices. We also operate a specialized intelligent design center and cleanroom facilities. With tangible, high-end equipment and advanced processes, we guarantee the quality and reliability that drive the success of your dental business.

Retech’s instrument kits are manufactured from high-quality medical-grade surgical steel, offering clinical suitability, rapid innovation, fast mass production, and consistent quality.

We provide products tailored to different surgical procedures to meet the specific compatibility requirements of various operations.

RAW MATERIALS

Selection of Raw Materials

Retech selects high-strength 402 surgical steel to ensure optimal clinical performance. The surface can be treated with a DLC coating to enhance durability and sharpness while preventing rust.

Strict inspection of raw materials to ensure they meet standards and requirements.

Establish self-inspection standards; employees conduct self-checks during production to ensure all stages meet quality requirements.

Critical Dimension Inspection: 100% inspection of critical dimensions to ensure products meet size specifications.

100% inspection of product functions to ensure proper operation.

Comprehensive inspection of completed products to ensure overall quality.

Monitoring of packaging processes to guarantee product protection during transportation.

Qualifications

Certificate of Honor

CE

ISO 9001

ISO 13485

FDA

Production Capacities

Production Capacities

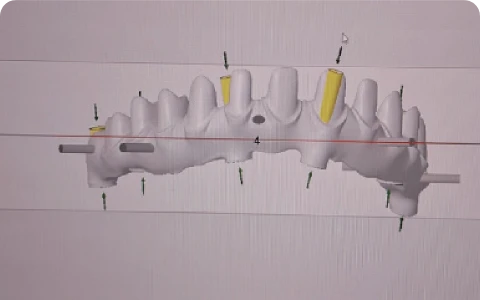

A dedicated drill and instrument production workshop allows new product

prototyping and mass production to be completed within two to three months.

OEM Services

OEM Services

OEM Customization Services

At Retech, we offer professional OEM manufacturing solutions for dental implant restoration accessories. Whether you have a sample to replicate or just an idea to bring to life, our engineering and production teams can turn your vision into reality.

Contact Info

Phone:+86 18268107619

Phone:+86 18268107619

Email:cherry@retechdental.com

Email:cherry@retechdental.com

Our Customization Process

01. Contact Us:

Use the contact details listed on our website to talk with our customer service team. Please note that due to time zone differences, response times may vary.

02.Submit Your Requirements:

Leave us a message describing your needs — whether it’s purchasing a specific item or outsourcing production for a product — and we’ll reply promptly.

03.Requirement Confirmation & Quotation:

We’ll communicate with you to finalize technical details and provide a quotation. Once approved, we’ll proceed to the next stage.

04.Contract, Delivery Date & Payment:

After price confirmation, we’ll prepare a formal contract, agree on shipping methods and timelines, and begin production after receiving your deposit.

05.Production & Quality Inspection:

We manufacture according to strict quality requirements and conduct thorough inspections to ensure every product meets standards.

06.Delivery:

Upon passing inspection, products will be shipped using your preferred delivery method.

China Domestic Orders: Free shipping

International Orders: Terms discussed separately

07.Final Payment:

Once you receive and approve the goods, the balance payment will be made according to the agreed contract terms

Frequently Asked Question

Lorem ipsum dolor sit amet,consectetuer adipiscing edit.

Aenean commodo ligula aenean massa.

How often should I have a dental check-up?

What should I do if I have a dental emergency?

What is your approach to pain management during dental procedures?

What options are available for replacing missing teeth?

How can I prepare my child for for their first dental visit?