ABOUT US

Dental Implant Manufacturer

The procurement team at Retech has established a world-class production line, carefully selecting CNC machines from renowned brands such as TORNOS (Switzerland), CITIZEN, and STAR (Japan). The equipment fully meets the production standards of leading international implant manufacturers, ensuring strong manufacturing capabilities.

The turning center's equipment achieves micrometer-level precision (0.001 mm), ensuring high product quality. Featuring multi-axis and multi-station capabilities, it reduces the number of setups and datum transfers, minimizing error accumulation and guaranteeing precise one-time processing from raw material to finished product. Under full load, it can produce up to 12,000 high-precision components per day and maintain a stable monthly output of 300,000 pieces, effectively meeting order demands nationwide. Through digitalized, large-scale production and meticulous management, costs are reduced while market competitiveness is enhanced.

Retech products are made from high-quality medical titanium alloys, featuring excellent biocompatibility, low elastic

modulus, low density,superior corrosion resistance, non-toxicity, high yield strength, long fatigue life, good room-temperature

plasticity, and ease of forming.

Scan Body

view more+

Ti Base

view more+

Cover Screw

view more+

Temporary Abutment

view more+

Impression Coping

view more+

Healing Abutment

view more+

Pre-milled Blanks

view more+

Analogues

view more+

Healing Cap

view more+

Multi Unit Abutments

view more+

Straight Abutments

view more+

Angled Abutments

view more+

view more

RAW MATERIALS

Selection of Raw Materials

Retech selects implant-grade Grade 5 titanium as the base material and chooses different raw materials tailored to specific product requirements to maximize product quality. Grade 5 titanium implants primarily use TC4 alloy, which is characterized by excellent overall performance and good manufacturability.

Retech's raw materials include not only the traditional TC4 alloy but also the improved TC4 ELI low-interstitial alloy. The TC4 ELI low-interstitial titanium alloy reduces the content of interstitial elements such as carbon (C), oxygen (O), nitrogen (N), and impurity element iron (Fe) compared to standard TC4, resulting in slightly lower strength but significantly improved toughness.

Strict inspection of raw materials to ensure they meet standards and requirements.

Establish self-inspection standards; employees conduct self-checks during production to ensure all stages meet quality requirements.

Critical Dimension Inspection: 100% inspection of critical dimensions to ensure products meet size specifications.

100% inspection of product functions to ensure proper operation.

Comprehensive inspection of completed products to ensure overall quality.

Monitoring of packaging processes to guarantee product protection during transportation.

Qualifications

Certificate of Honor

CE

ISO 9001

ISO 13485

FDA

Production Capacities

Production Capacities

The turning center is equipped with over 40 professional imported cutting machines, more than 30 customized abutment cutting and polishing devices, and over 10 inspection and calibration instruments. Under full load, it can produce up to 12,000 high-precision components per day, maintaining a stable monthly output of 300,000 pieces.

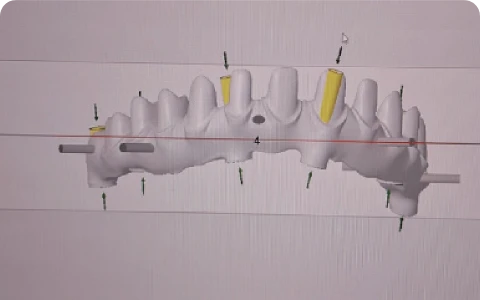

OEM Services

OEM Services

OEM Customization Services

At Retech, we offer professional OEM manufacturing solutions for dental implant restoration accessories. Whether you have a sample to replicate or just an idea to bring to life, our engineering and production teams can turn your vision into reality.

Contact Info

Phone:+86 18268107619

Phone:+86 18268107619

Email:cherry@retechdental.com

Email:cherry@retechdental.com

Our Customization Process

01. Contact Us:

Use the contact details listed on our website to talk with our customer service team. Please note that due to time zone differences, response times may vary.

02.Submit Your Requirements:

Leave us a message describing your needs — whether it's purchasing a specific item or outsourcing production for a product — and we'll reply promptly.

03.Requirement Confirmation & Quotation:

We'll communicate with you to finalize technical details and provide a quotation. Once approved, we'll proceed to the next stage.

04.Contract, Delivery Date & Payment:

After price confirmation, we'll prepare a formal contract, agree on shipping methods and timelines, and begin production after receiving your deposit.

05.Production & Quality Inspection:

We manufacture according to strict quality requirements and conduct thorough inspections to ensure every product meets standards.

06.Delivery:

Upon passing inspection, products will be shipped using your preferred delivery method.

China Domestic Orders: Free shipping

International Orders: Terms discussed separately

07.Final Payment:

Once you receive and approve the goods, the balance payment will be made according to the agreed contract terms

Here to Support You

Your success is our priority. Find resources and answers here,or reach out to our team for personalized assistance.

Does RE-TECH Dental participate in conference events?

What kind of company is RE-TECH Dental?

What types of products can RE-TECH Dental provide?

What are RE-TECH Dental's manufacturing capabilities?

What materials are used in RE-TECH Dental's products?

How compatible are RE-TECH Dental's products?

I have an idea for a product upgrade. Can you help me realize and manufacture it?